Increase Efficiency: Exactly How Updating Undercarriage Parts Can Improve Effectiveness

Increase Efficiency: Exactly How Updating Undercarriage Parts Can Improve Effectiveness

Blog Article

Essential Overview to Undercarriage Components for Heavy Equipment

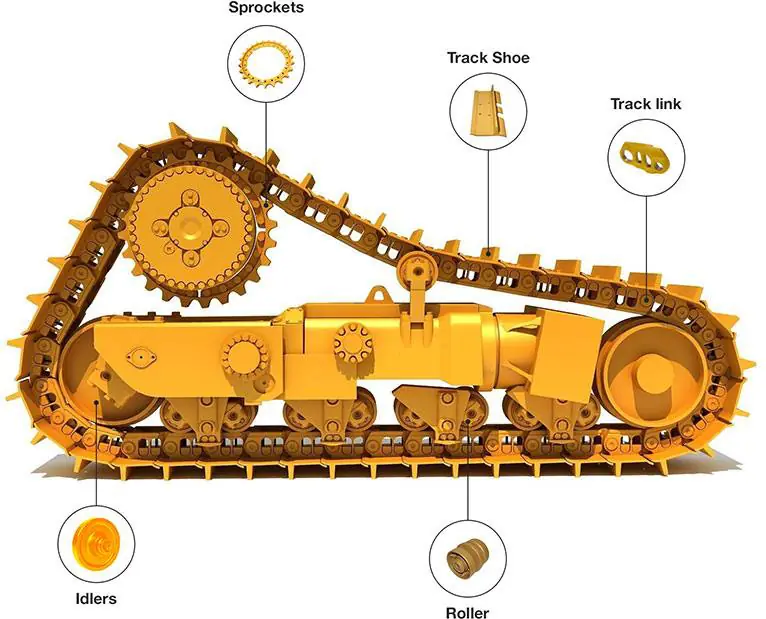

When it pertains to hefty tools, the undercarriage plays a vital function in making sure smooth and effective procedures. Understanding the elaborate information of undercarriage parts is important for taking full advantage of the lifespan and performance of your machinery. From track chains to rollers and idlers, each element contributes to the total functionality of the devices. Exploring the specifics of sprockets and other undercarriage components provides important insights into maintenance techniques that can significantly impact the durability of your hefty equipment. By understanding the significance of these components and their upkeep demands, operators can optimize the efficiency and durability of their equipment, inevitably leading to set you back financial savings and improved operational effectiveness.

Relevance of Undercarriage Components

Understanding the important role that undercarriage parts play in the performance and longevity of hefty tools is extremely important for reliable maintenance and operation - undercarriage parts. The undercarriage elements develop the structure on which the entire maker runs, supporting the weight of the equipment, supplying stability, and absorbing shock tons throughout procedure. A well-maintained undercarriage not only makes sure smooth procedure but also adds considerably to decreasing downtime and repair costs

The undercarriage consists of various crucial components such as track chains, track shoes, gears, idlers, rollers, and track structures. The track chains and track shoes aid in giving traction and assistance, while the idlers and gears assist in driving the tracks smoothly.

Sorts Of Track Chains

Track chains are important components of heavy equipment undercarriages, providing the necessary traction and assistance for reliable procedure. There are largely 2 kinds of track chains used in heavy tools: sealed and oiled track chains (SALT) and completely dry track chains. Sealed and lubed track chains are commonly discovered in modern-day heavy machinery. These chains are pre-lubricated and sealed to avoid dust, particles, and wetness from getting in the chain joints, making certain smooth procedure and prolonging the chain's life-span. On the various other hand, dry track chains need routine hand-operated lubrication to preserve optimum efficiency and prevent premature wear.

Duty of Rollers and Idlers

Rollers and idlers play a critical duty in sustaining and leading the track chains of hefty devices undercarriages, adding to the overall security and efficiency of the machinery. Idlers, on the other hand, overview the track chain and aid keep appropriate tension throughout the undercarriage system.

With each other, rollers and idlers function in consistency to make sure that the track chain remains in area, also on rough terrain, improving the devices's efficiency and this content longevity. Proper maintenance and routine evaluation of idlers and rollers are vital to protect against early wear and potential failures, eventually making the most of the effectiveness and life-span of hefty tools undercarriages.

Comprehending Sprockets

One essential aspect of gears is guaranteeing proper placement and tension to stop premature wear and damage. Misaligned gears can trigger irregular wear on the track chain, leading to lowered effectiveness and possible safety and security threats. Routine upkeep and assessment of gears are vital to determine any indications of wear or misalignment immediately.

Furthermore, gears can be found in different dimensions and tooth setups, relying on the details hefty equipment and its desired use. Appropriate choice of sprockets based upon the equipment's requirements is essential to guarantee ideal efficiency and longevity of the undercarriage system. Comprehending the duty of gears and their maintenance requirements is vital for making best use of the efficiency and life expectancy of hefty tools undercarriages.

Upkeep Tips for Longevity

To make sure the prolonged sturdiness and optimum performance of hefty devices undercarriages, attentive maintenance techniques are vital. On a regular basis inspecting undercarriage components such as track shoes, rollers, idlers, and sprockets for wear and tear is crucial. Appropriate track stress adjustment is additionally vital for minimizing premature wear on undercarriage parts.

Verdict

Finally, undercarriage components are vital elements for hefty equipment, playing critical functions in maintaining stability and capability. Understanding the different types of track chains, idlers, rollers, and sprockets is essential for proper upkeep and long life of the devices. By complying with upkeep pointers and consistently inspecting and replacing worn parts, drivers can make sure the optimum efficiency and efficiency of their heavy machinery. Appropriate treatment and focus to undercarriage components are vital to optimizing tools life-span and performance.

The undercarriage is composed of different necessary components such as track chains, track footwear, sprockets, idlers, look at these guys rollers, and track frameworks. The track chains and track shoes help in providing traction and assistance, while the idlers and useful reference gears assist in driving the tracks smoothly (undercarriage parts). There are largely 2 kinds of track chains made use of in hefty devices: sealed and lubricated track chains (SALT) and completely dry track chains. Correct choice and maintenance of track chains are important to guarantee the overall performance and long life of heavy tools undercarriages

Sprockets are indispensable elements of heavy tools undercarriages, accountable for transferring power from the equipment to the track chain.

Report this page